In a world where energy consumption is on the rise, our only hope is the development of new energy-generation technologies and energy efficiencies. Although currently used renewable energy sources such as wind and solar energy have their merits, there is a gigantic, permanent, and untapped energy source quite literally under our feet: geothermal energy. Temperatures at the surface of the earth are controlled by the Sun and the atmosphere, except for areas such as hot springs and lava flows. Generally in the Ottawa area, from shallow depths, say 2 m, to about 200 ft (61 m) below the surface, the temperature is constant at about 55°F (11°C).

This article describes the use of geothermal energy to heat Domestic Hot Water (DHW) and describes a method developed to control consumption efficiently as part of the Manotick microgrid, developed by Director, Canadian Club of Rome, Dr. Art Hunter.

While doing practice survival tests, three runs were conducted to see how long the entire home system could remain OFF-GRID. It was decided that there would be some soft energy rationing but nothing severe. The intent of the original test was to practice survival, determine candidates for energy efficiency rationing and make necessary hardware, firmware and software changes to extend the off-grid time by improving energy efficiency.

It was apparent from the first three runs that the longest off-grid run (exactly 14 days) was achievable by reducing the battery reserve level to near zero percent, delaying charging the Electric Vehicle battery until the sun was shining, reducing the amount of cooling air conditioning by opening windows at night and adjusting the domestic hot water heating cycle. These are the large and obvious target (low hanging fruit) energy efficiency options.

In order to stop prior overheating the hot water has resulted in what some may consider power interlock design overkill. However, this article is recording the result of changes over a 12 month period in 2018 and the design has subsequently been “downsized” to only those controls which are useful. The design objective was to use an existing heat pump and 30 gallon domestic hot water tank to mimic tankless heating by controlling the heat pump initiation activation time, duration and the DHW thermostat firmware settings. The existing hardware is configured to use an analogue sensor measuring the hot water tank temperature, which, according to the manually configured settings, will trigger a demand signal to the heat pump when the water temperature falls below a certain value (40 C) and then heat until the temperature is at or above the desired target value (45 C).

The objective is to deliver DHW to the shower head between 40 and 45 C at the required times. Under normal conditions the thermostat, by design, would constantly sense the DHW temperature and start the heater when the temperature dropped below 40 C and then heat until the temperature exceeded 45 C. Although this would have shower ready water 24 hours a day, it is highly energy inefficient.

The control technique used was to break into the demand signal cable and insert a timer switch to prevent the command demand from being sensed when OFF and to deliver the command when ON. This technique permits external time control allowing the commercial thermostat firmware to take charge. For example, if the DHW demand is blocked for a long time, like overnight, the temperature is likely to slowly decay to a temperature below the minimum of 40 C. In this example let us say it cools to 35 C. If the demand is activated at 07:00 until 08:00 in the morning, the 35 C is below the desired target of 45 C (as well as below the minimum of 40 C) and the command to heat is delivered to the Heat pump. There are now TWO controlling variables in the control system. The first is the thermostat firmware which is driving to elevate the temperature to 45 C and then to maintain it between 45 C and 40 C. The second is the timer which controls the start time and duration where the thermostat firmware can be active. This clock control becomes very important as it sets when the thermostat is activated and when it is deactivated.

Returning to the example suggests that terminating the heating cycle too early, say after 5 minutes, would prevent the temperature from achieving the target temperature of 45 C. Also, conversely, leaving the heating cycle to run for a long period, say 8 hours, would guarantee the target is reached but would be extremely energy inefficient as the temperature would never be allowed to dip below 40C. Further, the example picked a random 35 C as a starting temperature whereas in reality the starting DHW temperature would be somewhere between 10 C and 45 C. Of course, the colder temperatures take longer to heat a full tank of water.

If the starting temperature was already between 40 C and 45 C, then there would be no response. Water heating would only take place once the temperature dropped to 40 C or less.

The issue becomes deciding when to start and when to end the heating command. This solution requires estimating a start and duration, monitoring heat pump activity and then returning to tighten the control times. A future small design change will be to measure the temperature digitally and issuing appropriate commands through the Raspberry Pi computer. This change is in the planning phase.

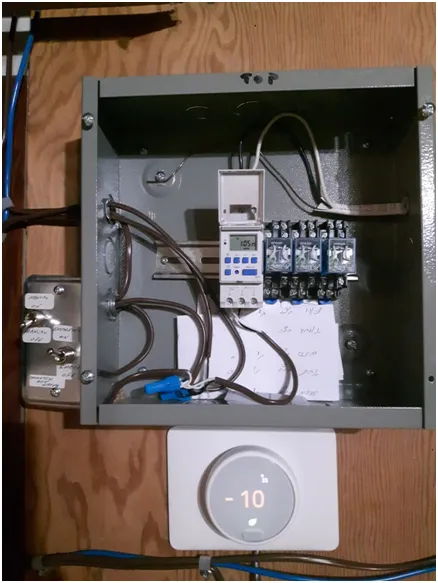

Below are the switches that are now running in parallel so that any one of them (or all of them) can connect the demand command.

Switch #1: This is a simple ON/OFF manual toggle switch on the far left of the picture. The demand signal voltage is 24 VAC and using milliamps of current with little danger of fire or very unpleasant unintended consequences. The short circuit failure mode is into a failsafe condition — being the way the system was designed by the supplier while the open circuit failure mode means there is no hot water being produced. Most of the time during the day the DHW control is configured for open circuit. It works but it means the operator has to be present to take charge of the switch. This is not a long term solution but very useful during development.

Switch #2: A surplus NEST thermostat was repurposed to do the switching according to a schedule resident on the NEST website but is also manually adjustable (ON/OFF) by rotating the disk. This white thermostat is shown at the bottom of the picture with a temperature setting of 10 C (meaning OFF as the ambient temperature was about 21 C). The downside is that Internet access is required for an automated switch. Also the minimum time duration for the NEST between ON and OFF was 1 hour. It worked and the system ran like this for a few months. It was not energy efficient as it was heating the hot water longer than necessary due to the very long 1 hour minimum duration.

Switch #3: A 16 ON/OFF cycle mechanical timer switch was purchased which gave incredible control throughout a day with a 1 minute resolution in time initiations and duration. White switch #3 is shown in the middle of the picture beside three DPDT unwired relays waiting for assignments. Each week-day’s profile could be different with many timing features, including a manual ON/OFF which could replace switch #1 above. The ON/OFF schedules rapidly converged to heating the tank for only 25 minutes. Then there was the initiation issue as lifestyle could include returning from playing tennis requiring a shower. It required a simple manual intervention to turn on the heat and another to turn it off at some irregular interval that could not be predetermined. A better solution was required for irregular use.

Switch #4: This is a “countdown timer” in parallel with the three above and providing 5, 10, 30 minute buttons and 1, 2, 4 hour buttons prior to automatic disconnect. It is located in the main home hallway beside the heat pump home air thermostat (Thermostat on left and Switch #4 on right).

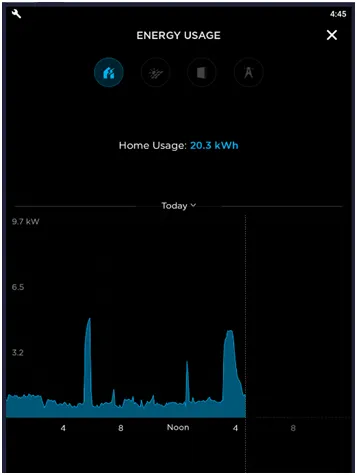

Testing in a true operational environment was undertaken by pressing the 30 minute button at 05:29 one morning. The picture below is the home consumption profile for some of that day.

The width of the pulse is 30 minutes exactly (automatically turned off at 05:59) and the measured consumption is nearly 2 kWh. Because this pulse was exactly 30 minutes in duration, suggests that the target of 45 C was not achieved. The water, according to touch, was certainly shower ready. In fact, for this experiment, timer switch #3 was to start at 7:00 but when that time arrived, the water was still above 40 C resulting in the heat demand command being ignored by the thermostat firmware. This is an excellent feature preventing accidental excess energy consumption.

As an aside there are two other energy efficiency considerations from the above. The first is the 3 p.m. connection of the Electric Vehicle to charge. It is always a large energy demand. The other is the background loads at about 600 watts running 24/7. This time of year there are three ceiling fans always on at low speed, two refrigerators, one small freezer, electric clocks, instant ON devices, internet routers and all home control system and displays in the control room. The phantom 600 Watts is something requiring a bottom up “search and destroy” activity.

Switch #5: A Ground Source Heat Pump command and Control Raspberry Pi3B switch (it is switch bank #8 of 16) was connected to run in parallel with the rest. Software switch management code has yet to be written but it will include its own temperature sensor measuring the DHW. However, it is harmless right now so it is still a manual option for activation from existing software.

Switch #6: This is a DPDT Emergency OFF manual switch that cuts off all the 5 above so the Domestic Hot Water is never heated automatically. In an emergency, all scheduled hot water heating is terminated and only used with manual control driven by need, say 2 showers a week or some form of Draconian energy rationing. This can also be thought of as a VACATION switch to stop heating hot water when on vacation.

To summarize, switches 3 and 4 will be the baseline to cover off routine daily life demands and the occasional shower or hot water demand that comes up from time-to-time. The other switches exist only for backup during failures, emergencies, vacation, development or future growth.

Reducing the ENERGY Footprint:

Primary Energy Footprint reduction candidates:

- Domestic Hot water. Developments to date are 1.1 to 2.0 kWh for each heating event. Typically a day will have three scheduled heating events without rationing.

- Heating and cooling. This is a big energy footprint. The best way to reduce this is with passive techniques to seal (stop air leaks) around windows and doors and to add insulation to slow heat loss. Thermal window shades are important but take care as the best ones reside within 3/8” of the glass. Bigger air gaps permit much more air movement reducing effectiveness substantially.

- Electric Vehicle charging. The only way to reduce this is to drive less. Hence car pooling and other alternatives are encouraged.

- Home Parasite Loads. Analysis and measurements have concluded that this house has a base energy load of 18 kWh per day (midnight to midnight). This consists of running computers, two refrigerators, freezer, four ceiling fans, instant ON devices like the TV, clocks, driveway light, three WIFI routers, sump pump, radio, TV, music, and many smart home Internet of Things hardware items which are combined with microgrid hardware. However, this 18 kWh is an interesting target that can be attacked one kWh at a time. For example, two “smart Plugs” were purchased which permit smart phone and automatic switching ON/OFF some parasite loads. Take the TV as an example. It has a box that links the satellite dish to the TV that is always ON and the TV itself is INSTANT ON. These two were put on an automatic OFF from midnight to noon (12 hours duration) which is well within lifestyle demands and exceptions can be managed with a smart-phone app to turn it ON. Other candidates will be identified and tried to see if this 18 kWh can be beaten back.

The sunset to sunrise home power consumption without EV charging, DHW or heating/cooling is about 13.5 kWh which grows to 18 kWh over 24 hours. 13.5 kWh is the capacity of one Tesla Powerwall battery. Intuitively, one could easily accept this load could be reduced by at least one kWh without significant degradation of operational capacity or safety/convenience/lifestyle. The only open issue is HOW. The four ceiling fans rank high on the target list.

The DHW was manually activated at 05:30 for 2 hours and recalling the automatic activation started at 07:00 for 25 minutes, the two ON commands overlapped for a total 2 hr 15 min duration. In the meantime, the heating was completed in 25 minutes, a shower was taken at 07:00 and the thermostat control system, although unrestricted for this time, did not detect the water temperature dropping to 40 C or less, hence it did not activate a demand signal. At 07:45 new commands were blocked and the DHW was left to drift down in temperature at its engineered rate of heat loss.

This proves that a manual activation of a heating demand two hours ahead of use will not result in more energy consumption compared to activation half an hour prior to use.

Development is a many day process to make time adjustments then monitor energy consumption and the human reaction to shower head water temperature. This process was not finished when this article was written. However, this micro adjustment of timers has slowed to once very few months as the occupants become “trained” to this new normal routine.

Nice blog. Thanks for sharing.